In this article, you learn about what is arc welding and how arc welding works. Here you will also learn about different types of arc welding, welding equipment, advantages and disadvantages, and applications.

What is Arc Welding?

The process of joining metal to metal with the help of an electric arc is called arc welding. In this welding process, the arc is used to create intense heat and this heat is used to join the metals together. The arc is brought in between two metal pieces and due to the heat generated, the metals melt and when it cools a strong welded joint is formed.

- The power source used in arc welding is electricity (electric current). The electric current used may be either direct current (DC) or alternating current (AC).

- The welding region is protected by some shielding gas, vapors, or slag. The shielding gas protects the weld area from atmospheric contamination.

- It can be manual, semi-automatic, or fully automated.

- It uses consumable or non-consumable types of electrodes for the welding purpose.

- This type of welding is invented in the late 19th century. In World War II, it became commercially important in shipbuilding. Nowadays it is used in the fabrication of steel structures and vehicles.

Types of Arc Welding

1. Shielded Metal Arc Welding (SMAW)

2. Gas Metal Arc Welding (GMAW) or (MIG)

3. Flux-Cored Arc Welding (FCAW)

4. Submerged Arc Welding (SAW)

5. Gas Tungusten Arc Welding (GTAW) or (TIG)

6. Plasma Arc welding (PAW)

7. Atomic Hydrogen Welding (AHW)

8. Carbon Arc Welding (CAW)

9. Electroslag Welding (ESW)

10. Electrogas Welding (EGW)

11. Stud Arc Welding

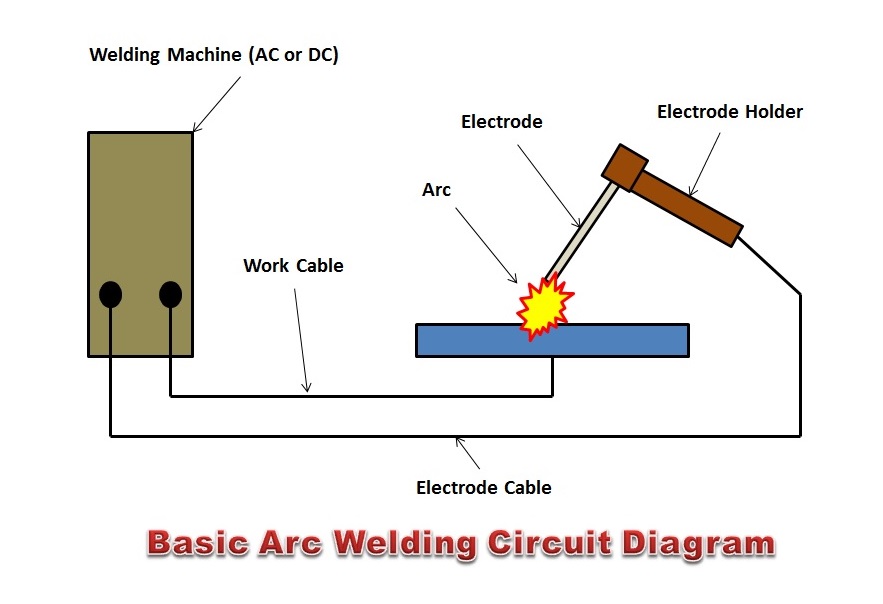

Basic Circuit Diagram of Arc Welding

The basic circuit diagram of arc welding is given below:

Main Equipment Of Arc Welding

The various equipment used are:

1. AC or DC machine

2. Electrode

3. Electrode holder

4. Cables, cable connectors

5. Chipping hammer

6. Earthing clamps

7. Wire brush

8. Welding Helmet

9. Safety goggles

10. Hand gloves

11. Aprons, sleeves, etc.

Also Read:

- What is Underwater Welding and How it works?

- Resistance Welding – Principle, Working and Application

- Friction Stir Welding – Working Principle, Advantages, Disadvantages with Application

Working of Arc Welding

- First ON the electric power source ( AC or DC).

- As the electrode is brought near the base metal ( 2-4 mm apart) where the welding is to be done, spark or arc starts to produce in between the base metal and electrode.

- Intense heat is generated due to the arc produced. The heat produced melts the base metal, electrode core ( or filler material in some case) and flux coating. The flux coating on the electrode provides a shielding environment (shielding gas) to the weld from the atmospheric contamination. The molten metal or slag gets deposited in between the two metal pieces to be joined and gets solidifies. After solidification, it forms a strong bond between the two metal pieces.

- Shielding gas is used to protect the melt or weld from atmospheric contamination.

- After completion of the welding process, the job (metal pieces) is cooled down by dipping it in an appropriate coolant. It can also be left for air cooling.

Advantages of Arc Welding

- It has high welding efficiency and speed.

- It provides a better welding environment.

- It gives a consistent quality of weld

- It forms a strong bond between the joined metals.

- It has simple welding equipment.

- The power source is not so expensive.

- It is a fast and reliable process.

- Equipment can be used for multiple functions.

- It is easily portable.

- Welders can use standard domestic current.

Disadvantages of Arc Welding

- A highly skilled operator is required.

Applications of Arc Welding

It is a versatile welding process. It is the most widely used welding process in the world because of its simplicity and good welding efficiency. Almost in every manufacturing industry, arc welding is used for producing strong joints. Today it remains an important process in the fabrication of steel structures and vehicles. It is most widely used in the automotive industries, construction industries, construction of buildings, shipbuilding industries, and aerospace industries, for maintenance or repair works.

This is all about what is arc welding. And if you find this article informative, then don’t forget to like and share it.