While doing welding process, we come across various types of welds. Sometimes we can’t understand a specific weld type or we know very less about that. But don’t worry by reading this article you will get an exact idea about each type. In this article, you will get to know each and every type. So, what are you waiting for? Let’s have a close look….

Types of Welds in Welding

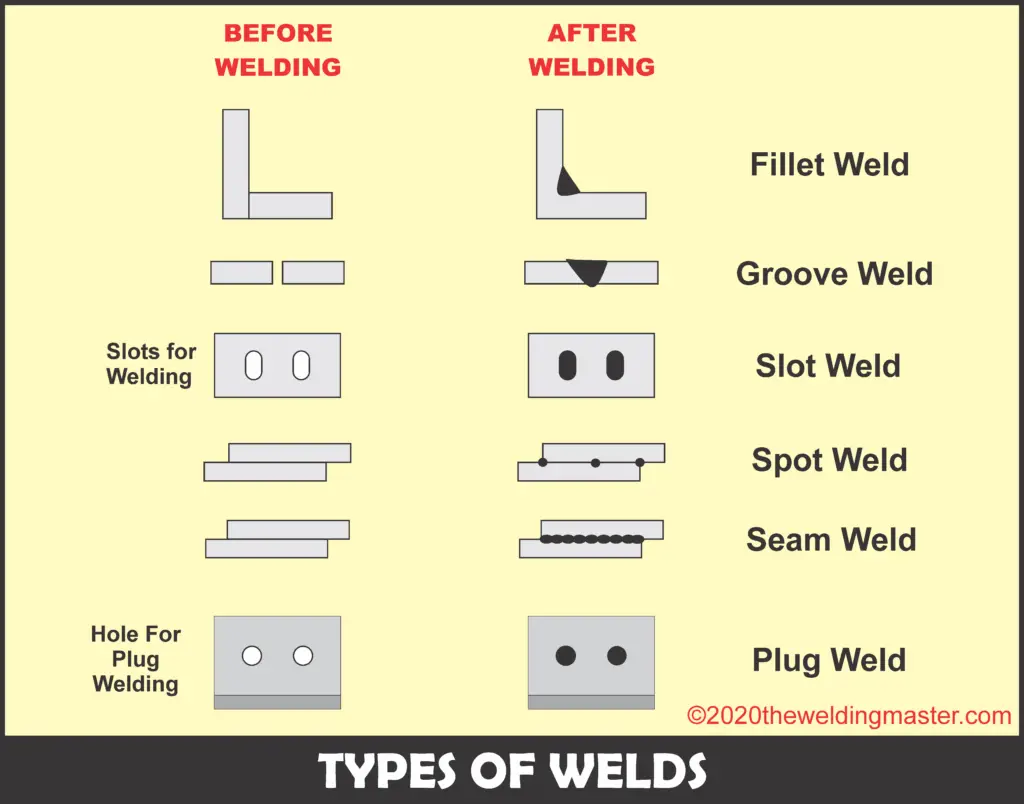

- Fillet weld

- Groove weld

- Slot weld

- Spot weld

- Seam Weld

- Plug Weld

- Surfacing weld

- Flash weld

1. Fillet Weld

A fillet weld is used to join two metal pieces together at right angles or at an angle. Fillet weld is commonly known as tee joint or lap joints weld.

- In T- joint, the two metal pieces are joined at the right angle to each other and in the lap joints, the two metal pieces overlap each other and welded at the edges.

- The weld obtained in the fillet weld is triangular in shape that may contain convex, concave, or flat surfaces depending upon the welder’s technique.

A fillet weld is used to join flanges to pipes and cross-section of infrastructure. It is also used for the welding cross-section when the bolts are not enough strong to hold it and wear off easily.

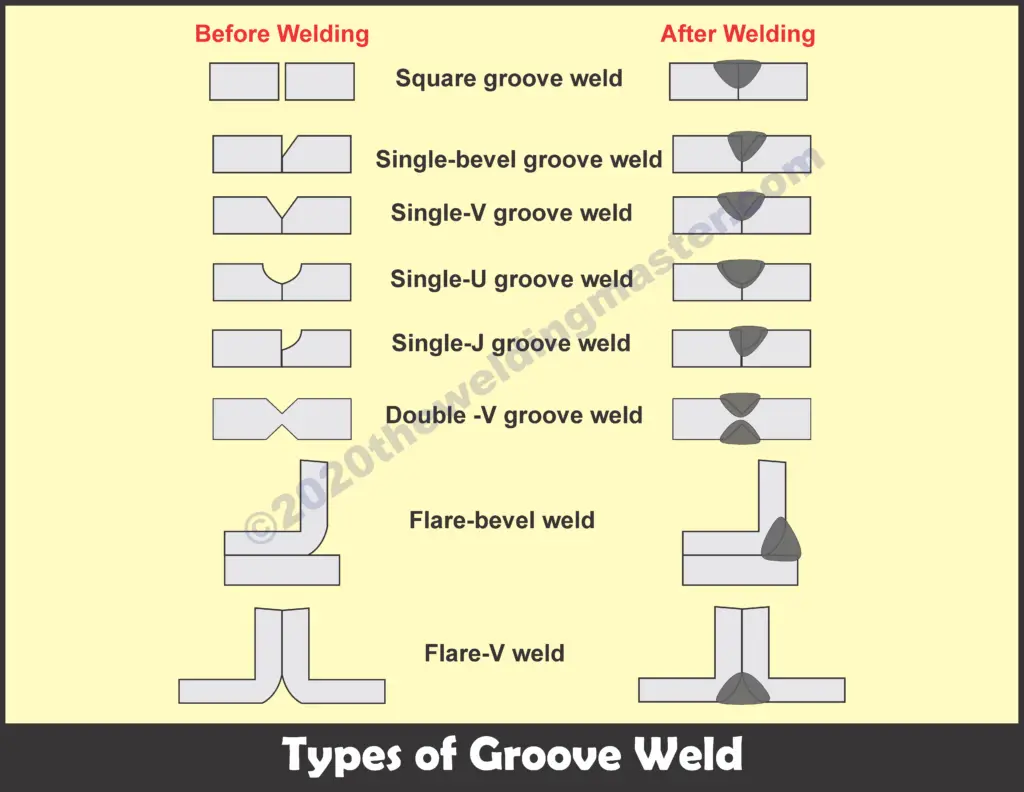

2. Groove Weld:

Groove weld is defined as an opening between the two joint members which provides the space to contain the metal. Groove welds are the most used welds after the fillet weld. There are seven basic types of groove weld:

- Square groove weld

- Single-V groove weld

- Single-bevel groove weld

- Single-U groove weld

- Single-J groove weld

- Flare-V weld

- Flare-bevel weld

The following figure shows all seven basic types of groove weld:

3. Surfacing Weld:

The process of deposition of a metal on another metal in order to get desired properties and dimensions with the help of a welding technique is called surfacing welding. And the weld we obtained is called surfacing weld.

Why do we Do Surfacing welding?

- To get desired properties on base metal: Suppose we have metal that has less wear resistance and we want to increase its wear resistance then we take a metal that has greater wear resistance and do surface welding. This way we get desired properties on the base metal.

- To build up broken surfaces of metals: Sometimes due to wear, the surfaces of metal part gets broken or worn out. So to build up the broken or worn-out surfaces we use surface welding.

Also Read:

- What is Arc Welding? How Arc Welding Works?

- Different Types of Welding Joints

- What is Welding Defects – Types, Causes and Remedies?

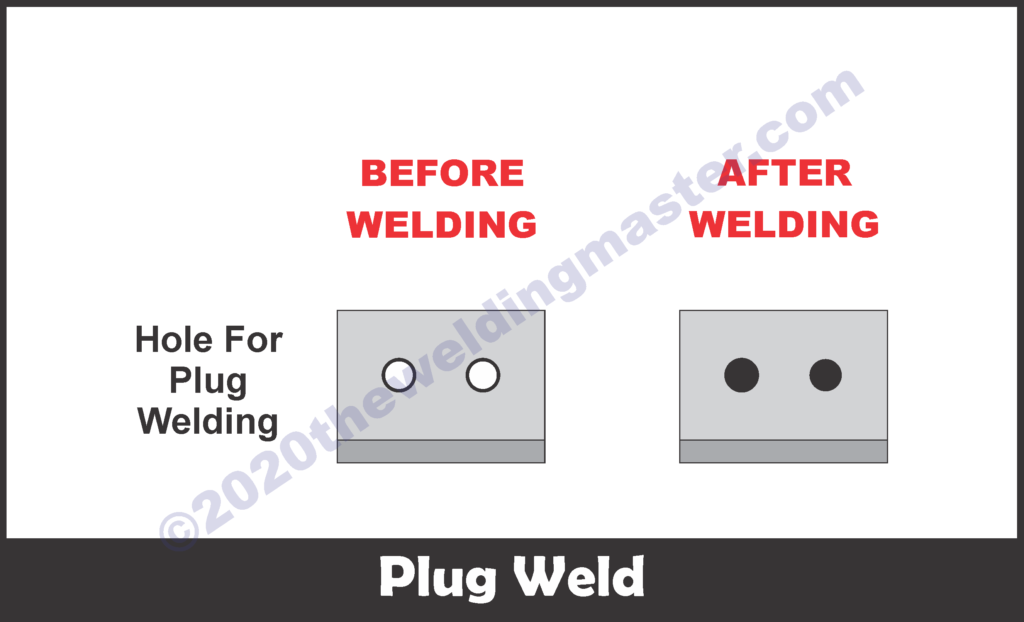

4. Plug Weld

A plug weld is used to lock two metal pieces together. It is mostly used if we want to join metal with different thicknesses. These types of weld are used when we have to weld inside a pipe. The shape of the plug weld is circular.

5. Slot Weld

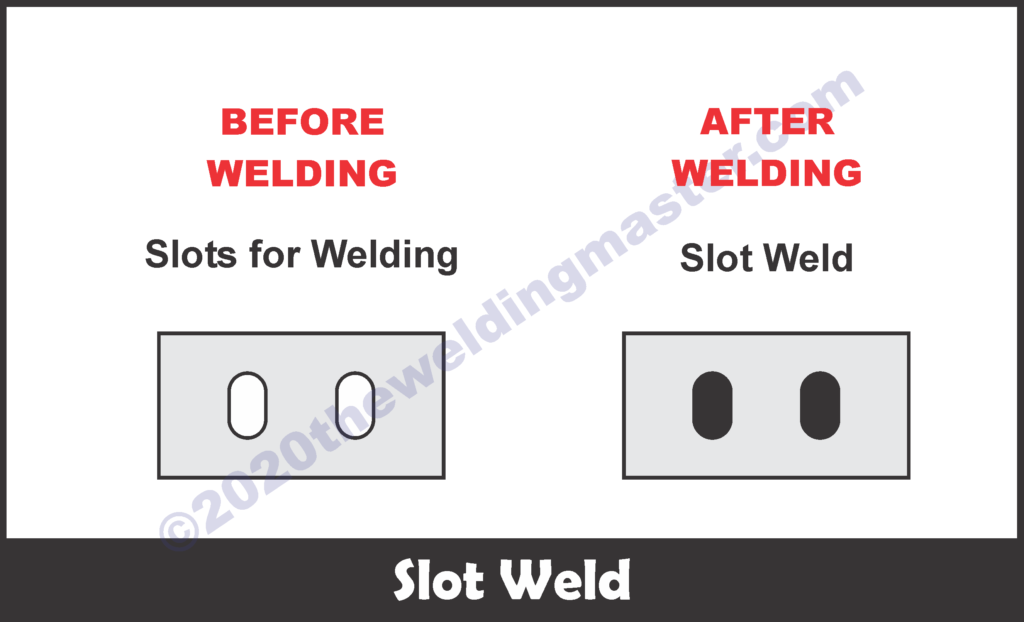

Basically, a slot weld join one surface of a metal to the other through an elongated cavity or hole. This cavity or hole may be partially filled with the weld metal or may be open at one end.

6. Flash Weld

Flash welding gives us a flash weld. While making the flash weld, there is no use of any type of filler metals. Here, the fusion is generated over the complete abutting (adjoining) surface. Here, heat is generated with the help of resistance to the current flow between the surfaces, and also pressure is applied to generate heat. This type of weld is used in the railroad industry.

7. Seam Weld

Seam weld is a continuous weld that is obtained between two overlapping members of a joint. Seam welding is obtained by using resistance seam welding.

8. Spot Weld

The weld that we get by doing spot welding is called spot weld. In this welding technique, the two metal pieces are joined together as spots. The adjoining surfaces of two metals have been spotted at a particular distance. Look at the diagram above to understand it clearly.

In this article, we learned about the different types of welds. Hope this article gives you clear information about the different weld types. If you got some worthy knowledge out of it, share it with your friends because “Sharing is Caring”