We all know about the arc welding process. But have you ever heard about the atomic hydrogen welding (AHW).? Well, this welding process is one of the types of arc welding processes. AHW has been known for carrying out the superior welding process. Inside this article, we will take a brief overview, its pros, cons, features, etc. So, let us take a close look at this welding technique.

Definition

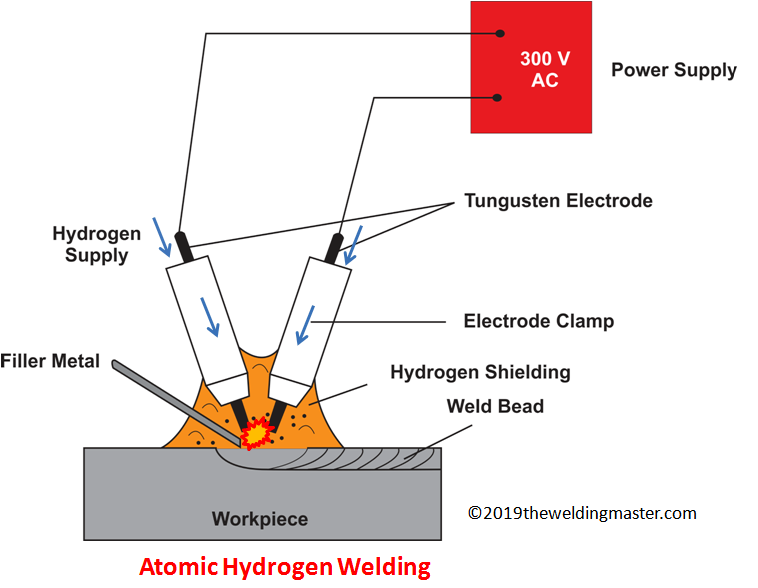

It is an arc welding process that uses an electric arc between two tungsten electrodes in the presence of hydrogen. The shielding atmosphere in the atomic hydrogen welding is consists of the hydrogen. Atomic Hydrogen Welding process is abbreviated as AHW.

History

We have been familiar with the arc welding process for many years. But the use of hydrogen in the arc welding process was not known to everyone. Later, Nobel prize winner Irving Langmuir invented AHW while he was studying atomic hydrogen.

In the atomic hydrogen welding, electric arc and hydrogen play a crucial role. The electric arc breaks the molecules of the hydrogen very efficiently. Later, these hydrogen molecules recombine and release a tremendous amount of heat. During the release of the heat, temperatures in the range of 3400 º to 4000 º are reached.

What do you think about carrying out this welding process in the absence of hydrogen?

From several studies, it has found that without an electric arc this process becomes quite inefficient. We can use the oxyhydrogen torch instead of electric arc but in that case, we can reach temperature only up to 2800 º C.

Equipment

- 2 electrodes of tungsten

- An electrode holder or a torch

- Hydrogen gas cylinder

- Filler rod/Metal

- A controller with 300 V power supply. AC power supply is used in the atomic hydrogen welding

The equipment involved in the AHW contains a welding torch with two tungsten electrodes. These two electrodes are inclined to each other. Also, they are adjusted in such a way that they will maintain a stable arc.

Around the two tungsten electrodes, an angular nozzle is present which carries the hydrogen gas, Gas cylinders are used for the storage of the required hydrogen gas.

Why is the AC power supply used instead of DC?

This question may come to your mind while thinking about the power supply in the atomic hydrogen welding. In this process, we have to maintain an equal supply of heat at both ends of the electrode. Without the equal supply at the ends of the electrode, we cannot carry out this process in the proper way. Therefore, to get the required equal supply of heat at both ends, we have to use the AC power supply instead of DC in the AHW process.

Also Read:

- What is Underwater Welding and How it works?

- What is TIG Welding Process or Gas Tungsten Arc Welding (GTAW)

- Plasma Arc Welding Process- Principle, Main Parts, Working, Advantages and Disadvantages with Application

How Atomic Hydrogen Welding Works?

Arc generation takes place when two electrodes of tungsten are kept in contact with each other. Also, after making the contact they are separated by a small distance of 1.5mm.

Below is the diagram about the AHW process:

When the electric arc passes through the hydrogen gas, it dissociates into the atomic hydrogen. This dissociation into the atomic hydrogen happens due to the absorption of a large amount of heat produced in the process.

Here the endothermic reaction takes place.

H2= H + H -422 KJ

After that, the recombination of the atomic hydrogen takes place. This recombination takes place as the atomic hydrogen touches the cold workpiece. This process liberates a large amount of heat.

H + H = H2 =422 KJ

Here, the exothermic reaction takes place during the recombination.

Atomic Hydrogen Welding Process:

Heat supplied must not be too large or too little. If the fusions process takes a long time then, it is the sign of having too little heat.

A proper arc gap should be maintained. It must not be too large or too small. If the proper arc gap is not maintained then, very little heat will be released.

Less heat will result in a small pool. Maintain the proper surface porosity will be very difficult if less heat is present.

Large heat will result in a wide pool. Excess amount of heat makes a large hole in the weld material.

Four factors that affect the success of Atomic Hydrogen Welding process:

- Speed of travel

- Arc size

- The setting of the current

- Proper contact of the workpiece with the arc.

For Better Understanding Watch the Video Given Below:

Advantages

- AHW produces very less distortion. The less distortion is due to the very intense flame. This intense flame produced can be concentrated at a particular joint.

- Atomic Hydrogen welding gives you a faster welding process. A faster welding process is always beneficial for welders and it also saves time.

- In the AHW process, there is no requirement of the flux separately. Hydrogen gas works as a shielding gas and prevents the oxidation of metals as well as of the tungsten electrode.

- In some welding processes, the workpiece is the part of the electric circuit and due to these situations like striking the arc and maintaining the arc column arises. But, as the workpiece is not part of the electric circuit in the AHW, there are no such problems during the entire process.

Key features regarding atomic Hydrogen Welding:

- The average temperature of the flame produced in this process is around 4000º C. This considered as the 3rd hottest flame.

- The temperature of the di-cyanoacetylene flame is around 4987º C and that of the cyanogen flame is around 4525º C.

- In the atomic hydrogen welding, the electrode life is increased by passing the hydrogen gas through the tungsten electrodes. Also, as hydrogen gas passes through the electrodes, electrodes get cooler.

- Recently, automatic AHW has been developed. In this process, hydrogen from high-pressure cylinders is not used. Instead of that hydrogen is obtained from the anhydrous ammonia.

- The heat produced in the AHW can weld tungsten efficiently.

Disadvantages

- For carrying out the atomic hydrogen welding process, a skilled labor supply is required. Without skilled labor, this process cannot be implemented efficiently. So, a talented and experienced labor work is a must.

- The cost of this welding process is slightly higher than that of the other welding processes. So, you must require a minimum capital to do the AWH.

- AHW is limited to only flat positions. For other positions, this welding process is not suitable.

- Required precautions should be taken as hydrogen is involved in this process. Hydrogen is a highly inflammable gas.

Applications

- Atomic hydrogen welding is used in the applications where we require fast welding. This welding process is mainly used for stainless steel and some special alloys.

- It can also be used for almost all the ferrous as well as non-ferrous metals.

- It is an ideal process for welding thin as well as thick sheets of metals with diameters in the range of 2 to 10 mm.

In today’s world, this process is sometimes replaced by gas metal arc welding. As the inexpensive inert gases are present at the larger amount, gas metal arc welding is used instead of the Atomic Hydrogen Welding.

Thus, in this article, we have discussed all the atomic hydrogen welding, its history, advantages, applications, how it works and all other its parameters. Thanks for reading this article and let us know in the comments your opinions about it.