When we hear the name welding, a lot of welding techniques come to our minds. In today’s article, we will learn about one of the most useful welding processes, seam welding. This welding process is very interesting to know. So, keep reading this article to know all about It.

What is Seam Welding?

Seam welding is a welding technique in which two similar or dissimilar metals are connected by supplying an electric current and in this process a nugget formation takes place. Mostly, these nuggets are formed in the form of a butt or overlapping welding components. Do you know the meaning of these nuggets? Well, the nuggets are nothing but small pools of molten metal which are formed at the location with high electrical resistance. Seam welding is one of the types of Resistance welding.

Working Principle of Seam Welding

The working principle of seam welding is similar to the working principle of resistance welding. According to the working principle of seam welding, the heat required at the time of the welding is produced due to the resistance of the material.

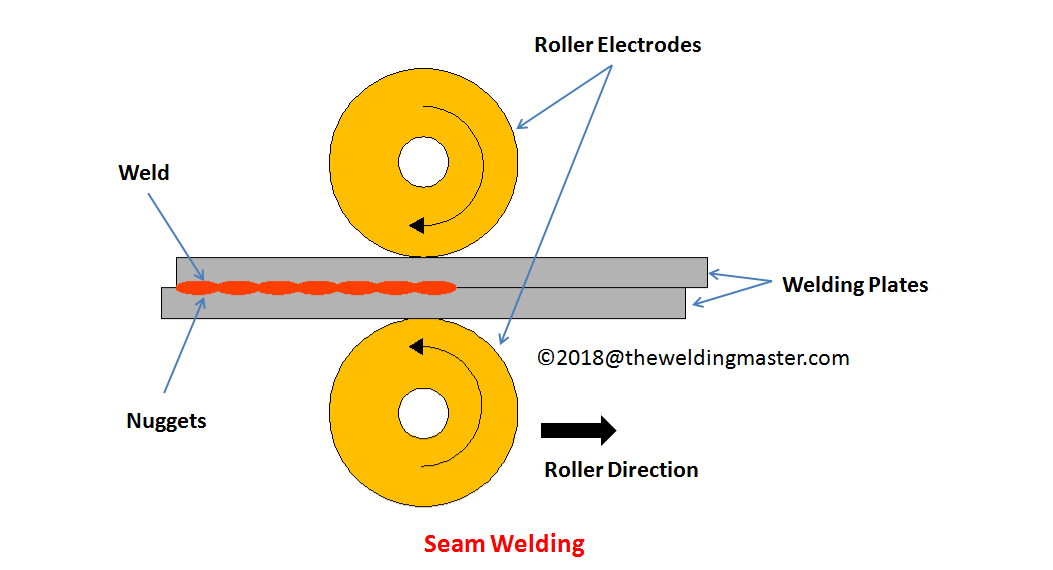

In simple language, heat generation takes place due to the resistance of the material. Have you ever heard about continuous spot welding? Continuous spot welding is nothing but seam welding. In seam welding, we use the electrode of roller type. The two rollers have an identical size. Here, these roller type electrodes are brought in contact with the workpiece. Then, the electric current is supplied to these rollers.

As the supplied current is very high the interface surface between the roller and the workpiece starts to melt and thus, a strong weld joint is formed. After that, these rollers start to rotate on the surface of the workpiece. As these rollers move, a generation of a continuous joint is formed. Are you curious to know about the welding speed in case of the seam welding? Well, the welding speed is 60 in/min in this welding technique. This speed is assumed to be standard but if you consider the practical applications then, there are chances that this speed may increase or decrease.

Also Read:

- What is Forge Welding and How it Works?

- Types of Welding Process – Everyone Should Know

- Explosive Welding – Equipment, Types, Working, Advantages and Disadvantages with Application

Below image will convey the exact process of seam welding. Here in the image, you can see that the two roller types of electrodes are moving on the plates. And between these two plates, you can see the formation of the weld.

Precaution

A most important precaution that you must take while performing seam welding:

Whenever we consider any welding process, then there are many precautions that we have to take in order to make that welding process a successful. The same case holds true for the seam welding. In the case of seam welding, you have to take care of the current that you are supplying. If the supplied current is too high then, the interface between the welding plates and roller will be very hot, in such conditions seam welding cannot be done properly. Also, you must be aware of the welding speed while carrying out this process.

To do the seam welding more effectively, sometimes the weld area is washed with water so that the roller type electrodes will remain cool while the entire process.

Types of Seam Welding

There are two types of seam welding:

- Intermittent Motion Seam welding

Here, the roller moves but its speed is not predetermined as that of the continuous motion seam welding.

- Continuous motion seam welding

In continuous motion seam welding, the speed of the roller type electrode is always determined first, and then, the current is supplied.

Also Read:

- Electroslag Welding Process – Principle, Main Parts, Working, Advantages and Disadvantages with Application

- Friction Welding Process – Working, Types, Advantages, Disadvantages with Application

- Resistance Welding – Principle, Working and Application

Advantages of Seam Welding

Let’s have a close look at the advantages of this welding process.

- This welding is known for forming the clear weld.

- There are only a few types of welding processes during which no gas formation takes place or not any other fumes are emitted. And the seam welding is one such type of welding process.

- Another benefit of this welding process is that there is no requirement for filler material during this welding method.

- Nowadays, every field in the world is becoming automating. Seam welding can be automated so there is no need of addition labors for doing this process.

- Do you want the simultaneous formation of the single seam weld and parallel seam weld? Then, the seam weld is only for you. This welding process produces the parallel seam weld and the single seam weld at the same time.

- With the help of continuous spot welding, you can form the gas-tight as well as liquid tight joints.

Disadvantages of Seam Welding

- This welding process is very difficult to carry out for the sheets of metals which have a thickness larger than 3 mm. So, it is suggested that use this technique if you have sheets of metals which have a thickness smaller than 3 mm. In simple world, it is not applicable if you have metal pieces above a specific thickness.

- You have to follow a particular path in this welding process. That means that rollers always move in a straight line. So, if you want to make a weld at some complex place then, this process is not applicable.

- There is a need of highly-skilled operator or a machine that can handle the speed of the roller as per the situations.

- The machinery that is used in this welding has a very high price. Due to the excessive equipment cost, it is used in a very small proportion.

Applications of Seam Welding

- It plays an important role in the manufacturing of all types of barrels as well as almost every type of exhaust system.

- Its large number of use is done in the case of aircraft tanks, refrigerators, oil transformers, etc.

- It is also used in the welding of stainless steel, nickel alloys, and magnesium alloys.

The bottom line is that this welding process has a number of applications. It has some advantages as well as disadvantages but it is quite superior to other welding techniques. Though there are some drawbacks it can be used where you require uniform welding in a straight line.

We hope that you like this article and we explained to you all the details about seam welding. If you like this article then, it is time to share it! And remember “Sharing is Caring!”