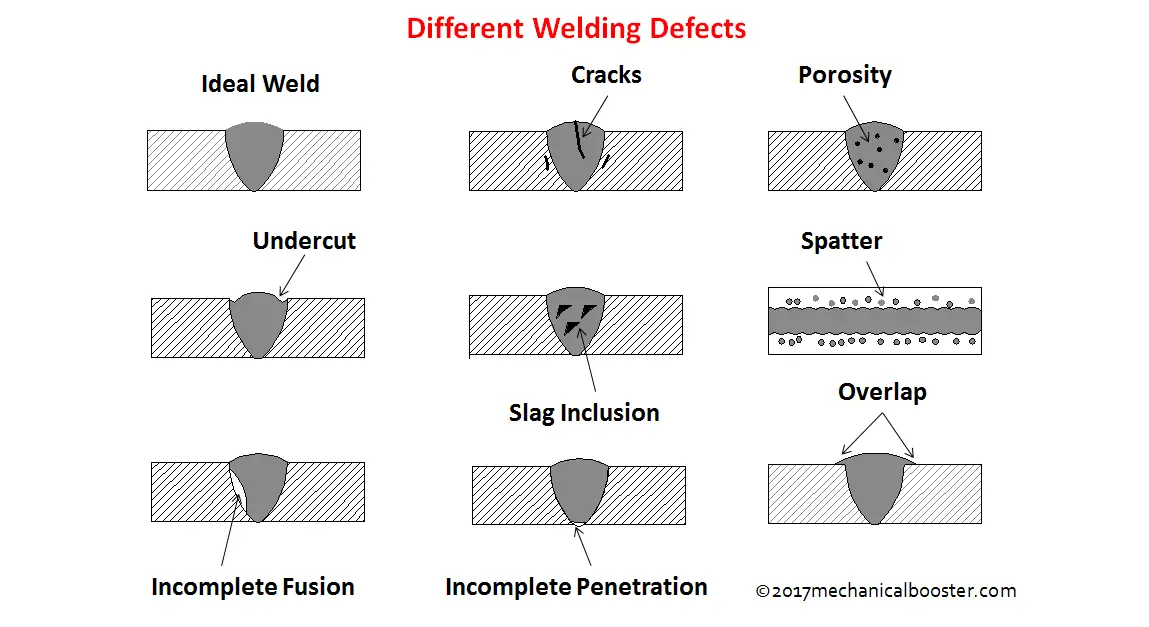

What are Welding Defects?

Welding Defects can be defined as the irregularities formed in the given weld metal due to wrong welding process or incorrect welding patterns, etc. The defect may differ from the desired weld bead shape, size, and intended quality. Welding defects may occur either outside or inside the weld metal. Some of the defects may be allowed if the defects are under permissible limits but other defects such as cracks are never accepted.

It is also highly recommended to wear personal protective equipment such as welding helmets, gloves, jackets, boots, goggles, etc while working on the welding. These types of equipment protect the welder from sparks, spatter, fumes, extensive heat, etc generated during the welding process.

Types of Welding Defects

Welding defects can be classified into two types : external and internal defects:

External Welding Defects:

1. Weld Crack

2. Undercut

3. Spatter

4. Porosity

5. Overlap

6. Crater

Internal Welding Defects:

1. Slag Inclusion

2. Incomplete Fusion

3. Necklace cracking

4. Incompletely filled groove or Incomplete penetration

External Welding Defects

The various types of external defects with their causes and remedies are listed below:

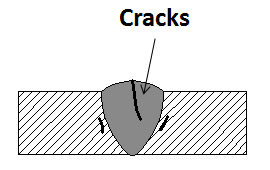

1. Weld Crack

This is the most unwanted defect of all the other welding defects. Welding cracks can be present at the surface, inside of the weld material or at the heat affected zones.

Cracks can also appear at different temperatures:

Hot Crack –

It is more prominent during crystallization of weld joints where the temperature can rise more than 10,000-degree Celsius.

Cold Crack –

This type of crack occurs at the end of the welding process where the temperature is quite low. Sometimes cold crack is visible several hours after welding or even after few days.

Causes Of Weld Crack:

1. Poor ductility of the given base metal.

2. The presence of residual stress can cause a crack on the weld metal.

3. The rigidity of the joint which makes it difficult to expand or contract the metals.

4. If there is high content on sulfur and carbon then also the cracks may appear.

5. Using hydrogen as a shielding gas while welding ferrous materials.

Remedies for Weld crack:

1. Using appropriate materials may decrease the chances of crack.

2. Preheating the weld and reducing the cooling speed joint helps in reducing crack.

3. Reduce the gap between the weld joints by using reasonable weld joints.

4. While welding release the clamping force slowly which increases the fill capacity of the welding material.

Also Read:

- Types of Welding Process – Everyone Should Know

- Difference Between MIG and TIG Welding

- Types of Welding Electrodes

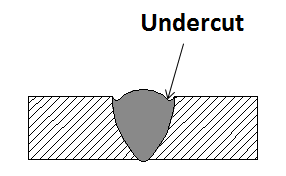

2. Undercut

When the base of metal melts away from the weld zone, then a groove is formed in the shape of a notch, then this type of defect is known as Undercut. It reduces the fatigue strength of the joint.

Causes

1. If the arc voltage is very high then this defect may occur.

2. If we use the wrong electrode or if the angle of the electrode is wrong, then also the defect may form.

3. Using a large electrode is also not advisable.

4. High electrode speed is also one of the reasons for this defect.

Remedies

1. Reduce the arc length or lower the arc voltage.

2. Keep the electrode angle from 30 to 45 degree with the standing leg.

3. The diameter of the electrode should be small.

4. Reduce the travel speed of the electrode.

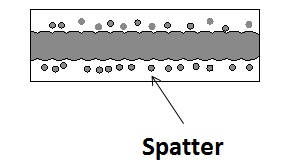

3. Spatter

When some metal drops are expelled from the weld and remain stuck to the surface, then this defect is known as Spatter.

Causes

1. High Welding current can cause this defect.

2. The longer the arc the more chances of getting this defect.

3. Incorrect polarity.

4. Improper gas shielded may also cause this defect.

Remedies

1. Reducing the arc length and welding current

2. Using the right polarity and according to the conditions of the welding.

3. Increasing the plate angle and using proper gas shielding.

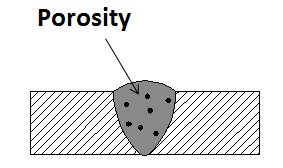

4. Porosity

Porosity in the condition in which the gas or small bubbles gets trapped in the welded zone.

Causes

1. It occurs when the electrode is not coated properly.

2. Using a longer arc may also increase its chances.

3. Increased welding currents.

4. Rust or oil on the welding surface.

Remedies

1. Proper selection of the electrode.

2. Decreasing the welding current.

3. Using smaller arc and slowing the process to allow the gases to escape.

4. Remove rust or oil from the surface and use a proper technique.

Also Read:

- Different Types of Welding Joints

- How Shielded Metal Arc Welding (SMAW) Works?

- What is Arc Welding? How Arc Welding Works?

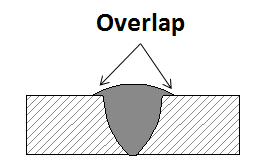

5. Overlap

When the weld face extends beyond the weld toe, then this defect occurs. In this condition the weld metal rolls and forms an angle less than 90 degrees.

Causes

1. Improper welding technique.

2. By using large electrodes this defect may occur.

3. High welding current

Remedies

1. Using a proper technique for welding.

2. Use small electrode.

3. Less welding current.

6. Crater

It occurs when the crater is not filled before the arc is broken, which causes the outer edges to cool faster than the crater. This causes a stress and then crack is formed.

Causes

1. Incorrect torch angle.

2. Use of large electrode:

3. Improper welding technique

Remedies

1. Using a proper torch angle may reduce the stress on the metal

2. Using a small electrode may also decrease the crater.

3. Use a proper technique.

Internal Welding Defects

The various types of internal welding defects with their causes and remedies are listed below:

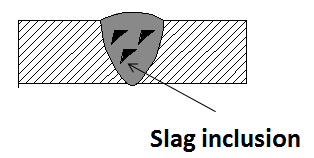

1. Slag Inclusion

If there is any slag in the weld, then it affects the toughness and metal weldability of the given material. This decreases the structural performance of the weld material. Slag is formed on the surface of the weld or between the welding turns.

Causes

1. Slag is formed if the welding current density is very small, as it does not provide the required amount of heat for melting the metal surface.

2. If the welding speed is too fast then also slag may occur.

3. If the edge of the weld surface is not cleaned properly then also slag may form.

4. Improper welding angle and travel rate of welding rod.

Remedies

1. Increase the current density

2. Adjust the welding speed so that the slag and weld pool do not mix with each other.

3. Clean the weld edges and remove the slags of previous weld layers

4. Have a proper electrode angle and travel rate.

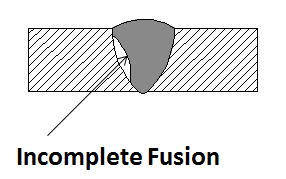

2. Incomplete Fusion

Incomplete fusion occurs when the welder does not accurately weld the material and the metal pre solidifies which leads to a gap which is not filled with the molten metal.

Causes

1. It occurs because of the low heat input.

2. When the weld pool is very large and runs ahead of the arc.

3. When the angle of the joint is too low.

4. Incorrect electrode and torch angle may also lead to incomplete fusion.

5. Unproper bead position.

Remedies

1. Increasing the welding current and decreasing the travel speed helps in removing the chances of incomplete fusion.

2. Reducing the deposition rate.

3. Increasing the joint angle.

4. Try to position the electrode and torch angle properly so that the edges of the plate melt away.

5. Positioning the bead properly so that the sharp edges with other beads can be avoided.

3. Necklace Cracking

It occurs in the use of electron beam welding where the weld does not penetrate properly. Therefore, the molten metal does not flow into the cavity and results in a cracking known as “Necklace Cracking”.

Causes

1. Improper welding technique.

2. It occurs in materials such as nickel base alloys, stainless steel, carbon steels and Tin alloys.

3. Using high speed of electron beam welding

Remedies

1. Using a proper welding technique reduce the chances of necklace cracking.

2. Using proper materials for welding.

3. Using a constant speed during the welding process.

3. Improper welding technique

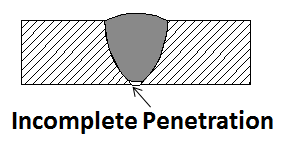

4. Incompletely Filled Groove or Incomplete Penetration

These defects occur only in the butt welds where the groove of the metal is not filled completely. It is also called as incomplete penetration defect.

Causes

1. Less deposition of the weld metal

2. Use of improper size of the electrode

3. Improper welding technique

Remedies

1. More deposition of the weld metal.

2. Use the proper size of the electrode.

3. By using a proper welding technique.

Conclusion

Here, we have listed all types of welding defects that may present during any manufacturing process. While welding, it is very important to remove all the defects of welding present in the workpiece. If there would be defects in the welding material, then in severe conditions the components of the material would fail which may lead to loss of property and sometimes also life.